Manufacturers of detergents, cleaners, cosmetics, sauces and condiments are more likely to use non-cylindrical containers, that are practical to handle and widely customizable in terms of shape, size and look.

Manufacturers of detergents, cleaners, cosmetics, sauces and condiments are more likely to use non-cylindrical containers, that are practical to handle and widely customizable in terms of shape, size and look.

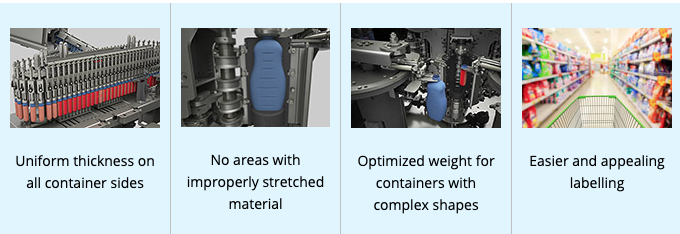

Getting high-quality non-cylindrical PET containers requires the use of blow moulding technologies of the latest generation, that ensure the uniform distribution of material over the whole surface of the container, in order to improve the efficiency of the production process and realize resistant and aesthetically perfect containers.

In a stretch-blow moulding plant it is thus necessary to asymmetrically heat the preforms through a differentiated heating system in order to obtain rectangular and oval containers with uniform thickness on all sides.