Competence, customized and cutting-edge solutions, efficient after-sales service, are the peculiar features that make Plasco an outstanding leader

Competence, customized and cutting-edge solutions, efficient after-sales service, are the peculiar features that make Plasco an outstanding leader

After having successfully installed a double centralized dosage station in northern Italy, Plasco srl, a company located nearby Ferrara (northern Italy) specialized in the developing and manufacturing of volumetric and gravimetric dosage systems for granule and powder, has installed another station in Tuscany and another one is under production for a company in Veneto.

There are several possible fields of application: from the food industry to the cosmetic-pharmaceutical industry, injection molding and recycling of plastic material, but the main one for this particular system is the blow film extrusion. Plasco’s strengths are versatility and competence, offering customized solutions, an excellent quality / price ratio to minimize return on investment, constant research for cutting-edge technological solutions and the efficient service of post-sales assistance, to satisfy the customer quickly and effectively.

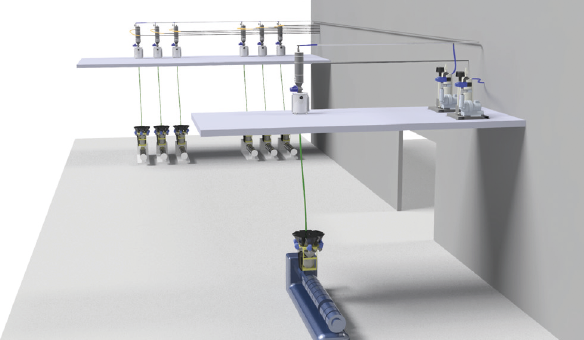

The last centralized system developed by Plasco has been installed in a major company located in the Tuscany region, producing high-level technical film for food and non-food packaging, with a capacity production of 1000 kg/h. This centralized dosing system has been designed to supply 8 extrusion lines, with the possibility of setting a different recipe for each line, choosing from 9 virgin materials.

Specifically, Plasco designed and built a customized gravimetric station for the preparation of the pre-mixes and the management of all material passages from the silos to the extruder. The various materials are taken from the silos with a centralized feeding system and stored inside the hoppers of the gravimetric station. When the system receives the material request from the extruder, the screw feeders dose the “batch” (recipe) inside a scale. Once completed, the recipe is discharged into a conveying hopper and immediately transported inside the mixer positioned above the extruder that had made the request. Subsequently, a cleaning sequence starts, carried out inside the scale and the hopper by means of a compressed air system to avoid contamination of materials. Since it is a completely automatic system, one of its advantages is the zeroing of material waste usually caused by the manual preparation of the recipes. The whole system is managed by a last generation Siemens PLC with a complex software, that is completely designed inside Plasco. The user interface, very intuitive thanks to a 3D graphic that mirrors the system, is realized with a touch-screen Panel-PC 12”. The operator simply needs to enter the required percentages for each component and associate the recipe to the destination line: the system will manage in full autonomy and with a mathematical algorithm, the safe preparation and transfer of the processed recipe. In this specific case, a communication protocol was also created to exchange data with the company management system, to comply with the “Industry 4.0” requirements. Furthermore, it is possible to have a traceability of the several materials used in the various recipes. The electrical panel is equipped with a remote assistance module to provide immediate customer support.

The Plasco system has made it possible to obtain various economic and productive advantages: a clean and efficient plant, a better quality of the finished product and the use of internal resources in a more rational way. Above all, the client was able to reduce the costs resulted by the material waste, caused by the manual preparation of the mixtures, he had before installing the new centralized dosage system.

With the acquisition of a well-known company specialized in industrial automation based on PLC-PC, software development, process controls, construction of electrical panels for plants and automatic machines, Pasco can broaden its market proposals, offering a 360-degree hardware and software service.

“Today our company is able to offer flexibility and competence that allow us to assist the client in a professional manner, proposing a technical and qualitative improvement of the production processes – says Martina Giatti, Plasco sales manager – The realization of this complex dosage and transport system is the confirmation.”