CMG Granulators launches the new G26 granulator line, for application with injection moulding, blow moulding and extrusion processes

CMG Granulators launches the new G26 granulator line, for application with injection moulding, blow moulding and extrusion processes

CMG launches the new G26 granulator line, for application with injection moulding, blow moulding and extrusion processes. Many are the very innovative and unique attributes of the new series and all contribute to obtaining the highest degree of productivity, regrind quality (homogeneous particle dimensions and absence of dust), efficiency of operation, cleanest environment and the lowest TCO. The standard configurations of the new series cover capacities starting from 50 kg/h all the way up to 300 kg/h.

3 Models, more than 30 configurations

The new G26 Line is made of three models: G26-30, G26-45 and G26-60. The line features integral sound enclosure and a very innovative feed hopper design to accommodate the widest variety of shapes and dimensions for the parts to grind. All models operate in high-efficiency conditions, are all equipped with EISA premium-efficiency motors and can have AMP controls (Adaptive Motor Power). Energy utilization is 20 Wh/kg vs the + 40 Wh/kg of conventional solutions.

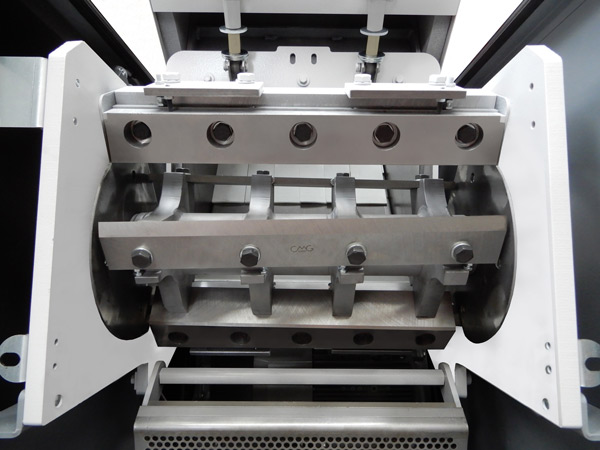

The new G26 Line is manufactured with the highest degree of materials and components. The very unique CMG cutting chamber is the signature feature of the new line. Totally assembled from CNC machined steel parts, fabricated with tolerances down to the hundredth of a millimetre, the very high degree of precision of assembly guarantees very accurate cut, dimensional homogeneity of the regrind particles and no generation of dust. Additionally, the high precision of fabrication reduces frictions and abrasions. No cooling water is necessary, irrespective of the application.

Accessibility and ease of maintenance

The new G26 Line introduces a very innovative design to favour accessibility for maintenance. All cleaning operations and maintenance needs can be fulfilled by accessing the unit from the front and by tilting the feed hopper, that is piston assisted. The cleaning operations take few minutes only and do not require the use of tools.

No powder generation or pollution

The regrind is evacuated from the granulator collection bin, positioned underneath the cutting chamber, by a full-vacuum regrind conveying system, another unique proprietary design by CMG Granulators. Vacuum conveying through large diameter steel piping ensures no mechanical stress of the regrind with consequent absence of generation of dust. Conventional thru-fan solutions are very detrimental to the quality of the regrind. An additional key benefit to the implementation of full-vacuum evacuation and conveying systems is the total elimination of pollution of powdery air to the surrounding environment.

The new G26 Line of CMG is equipped with integral controls that monitor all functions of the granulator unit itself and of all the ancillary elements, from the moment the part to recycle is dumped on the infeed conveyor all the way the regrind is conveyed into a surge bin for subsequent utilization or into a big bag for transportation to other locations. All CMG Granulators solutions are certified for compliancy to Industry 4.0.

Worldwide reach

With headquarters, production site and technical centre in Italy and the world’s largest distribution network in the plastics industry, CMG is active worldwide with service and sales centres and localized technical skills. Contact CMG at the following link https://www.cmg-granulators.com/en/contacts-3/