The strategic organization, the passion of its workers and the will to constantly improve allowed the company to become a fundamental player and commercial partner for many different clients all over the world

The strategic organization, the passion of its workers and the will to constantly improve allowed the company to become a fundamental player and commercial partner for many different clients all over the world

Born from the mind of Gianfranco Baracco, and today managed by his son Giovanni, Filtec has been a leader in the plastic material processing for over 29 years. The strategic organization, the passion of its workers and the will to constantly improve allowed the company to become a fundamental player and commercial partner for many different clients all over the world. Filtec aims to be the perfect solution for every customer and every need.

Filtec range of highly customizable products allows not only the granulation of plastic materials, including the more fluid ones that can be an obstacle for less technologically advanced machines. The Underwater and Water Ring systems are surely Filtec’s showpieces, but not less important are the vertical and horizontal Centrifuges, Screen-Changers, Vented Vibrating Screens and Water Filtering/Cooling Units.

The centrifuges are used both in washing and drying plants and allowing a fast cleaning and quality drying of pellets, flakes or chips. They can be supplied with different customizations like the rotor lifting system or the washing system of the external part of the screens for water-pellets separation.

The Screen-Changers are a high-quality solution for melted material filtration in granulation lines. They are available in different versions depending on the product that needs to be filtered.

The Vented Vibrating Screens are used for the cooling and separation of granules up to three different sizes and they work both as coolers and classifiers between granules, agglomerates and fines.

Finally, the Water Filtering/Cooling Units are used to filter and cool process water from our systems. We have studied and designed these machines in response to the growing need of savings in terms of resources used in the production system. Indeed, the advantages obtained from the reuse of process water are considerable.

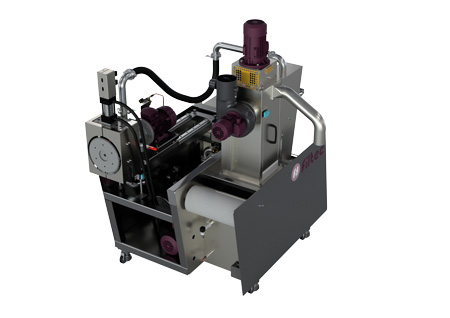

Small, compact and efficient: the new UW LAB

This year Filtec has decided to enrich its historical range of products, according to the market changes and evolution. Compact, easy to transport and excellent for producing minimum batches of material: the UW LAB is the new machine introduced by Filtec. The structure and technical configuration of the UW LAB are the same as those of an underwater pelletizer for big productions: therefore, all the advantages of a normal-sized UW can be found in the UW LAB but condensed into much lower dimensions and management costs. Suitable for any space, this new system guarantees reduced energy consumption, obviously without losing the efficiency and excellent performance of its “big brothers”. Even if depending on the material characteristics, the UW LAB has a maximum production capacity of approx. 40kg/h. It has been specially designed for particular needs such as carrying out laboratory tests, researching new materials and producing small quantity demonstrative batches. Furthermore, the UW LAB, as per Filtec tradition, can be customized in order to adapt to every need: from the connection flange to the die plate, up to the colour of the machinery itself, so that it can stand out or homogenize itself to your system. In addition, to ensure the quality of its machinery, Filtec can support its customers with a testing laboratory to study and know new materials behaviour.

Long experience behind a fresh and renewed look

The year 2022 will not only bring brand new machines and new ways to simplify their usage, but also a modernization of the longstanding logo and website. Being on the worldwide market for nearly 30 years, Filtec makes use its long experience but at the same moment recognizes the importance of offering a fresh and modern look, to attract new partners and, at the same time, to prove to the loyal clients that the company follows carefully, the development of the market not only in terms of technology and innovation, but also of aesthetic and renovation. Both the new logo and website are simplified and intuitive with modern design and customer-friendly interface, all to show the focus of the company on being the best partner it can be.

Towards a greener tomorrow

Even if the focus is on innovation, Filtec always shows its commitment to a greener future. Indeed, Filtec took the opportunity to teach the process of granulation and the importance of plastics recycling to children in first grade, to ensure that the good practices are transmitted among younger people and future generations. Filtec is also a founder member of the project Are You R, a community first born on Facebook and then supported by a web site can now allow to reach more than 80,000 contacts by Linkedin and Facebook.

The community shares the latest news about technological advancement about recycling and its results. This is one of the objectives that the project Are You R and Filtec have in common: that is, to realize that plastics are all around us and are very important materials, that need to be treated and processed in the right way. The increase in the usage of food and products delivery, electronic commerce and Personal Protection Equipment like surgical masks correspond to the increase in the production and consequently disposal of plastic packaging. It is essential for companies, whether big or small, to invest in new ways to optimize the processing of plastic materials.

For all these reasons, Filtec takes part to EU projects such as the last in time dedicated to the valorisation of waste coming from PPE, even sanitary ones and attends to social networks, to make itself more visible but at the same time to reach the younger age groups. The Facebook/Meta page can count on loyal followers and the YouTube channel is also growing and already enjoys more than 7,000 views. These two channels are constantly updated with video interviews, posts and shares from the “Are You R” Page, which offers numerous articles on recycling and the latest innovations in the circular economy.

International exhibition presence

Finally, not only social networks and the web are the answer. Filtec is in fact a permanent exhibitor of numerous sector fairs throughout Europe. Thanks to the almost total return to normality, this year Filtec has taken part in numerous fairs, such as Greenplast in Milan, Plastpol in Poland and PRS Europe in Amsterdam. Then in October Filtec will exhibit at the K-show in Düsseldorf, using this international stage to show the new UW LAB and other products. In all these events Filtec participated with architecturally updated stands, revealing and enhancing the new lines that will characterize the company’s brand from now on. This new image will accompany Filtec at the K Fair, where a large audience is expected at Hall 9 Stand E29.

These, some of the reasons why Filtec can consider itself an essential protagonist of the current market, and its will to evolve and develop will allow it to stay one for many years to come.