Lawer products, solutions and services supply the rubber, tire, plastic and food industries to increase reliability, safety and efficiency

Lawer products, solutions and services supply the rubber, tire, plastic and food industries to increase reliability, safety and efficiency

Founded in 1970, Lawer is an Italian company that specializes in industrial weighing systems. It has developed advanced technologies and know-how in the automatic weighing of powder products, including pigments, additives and chemicals, as well as single- or multi-weighting systems, and equipment for the preparation of compounds, fillers, masterbatch, handling and packaging systems. Its products, solutions and services supply the rubber, tire, plastic and food industries to increase reliability, safety and efficiency.

At the basis of all the production of the rubber industry are the recipes of the compounds. Complex formulations, expertly constructed with the contribution of many substances, whose quantities are rigorously predefined. The qualitative constancy of the final product therefore depends on the ability to feed the machinery of the mixing rooms with perfectly weighed doses and capable of perfectly respecting the proportions of all the required ingredients: raw materials, additives, dyes and much more. And this is where the competence and technological capacity of Lawer come into play.

Observing an ongoing trend among manufacturers to automate mixing rooms to improve product quality, safety, and hygiene, Lawer launched the second generation of its fully automated dosing systems for compound and masterbatch preparation.

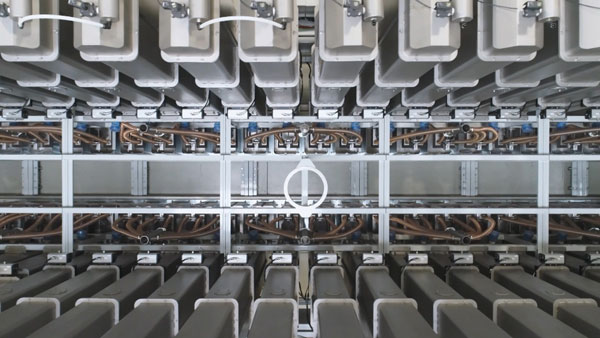

SUPERSINCRO is a horizontal automatic weighing system for chemicals used in the mixing room. It is a custom project that feed different materials, stored in silos, hoppers, big-bag and interchangeable silos, in a variable size bag produced automatically.

Comparison to the first generation SUPERSINCRO V2 includes:

– Higher productivity. Output up to one bag every 30”

– Higher accuracy. Up to a tolerance of ± 0.1 gr

– Higher repeatability. CPK more than 1.67

– Higher OEE. Overall Equipment Effectiveness

– Higher flexibility. Custom project configuration, variable bag size, and bag management till the mixing line.

– Less labour involved in the daily production

– Environment respect. Latest component version that helps to reduce the equipment footprint consumption.