Color Service presents a certified weighing system that ensures the most accurate calculations while dosing chemicals, and a modular design allows for future modifications

Color Service presents a certified weighing system that ensures the most accurate calculations while dosing chemicals, and a modular design allows for future modifications

Color Service is the world leader in the production and development of Automatic Dosing Systems for powder and liquid products for compound and masterbatch preparation.

The company’s technology is developed to solve problems associated with the manual weighing of pigments or additives and is designed with the aim to abandon traditional production methods that inevitably would not allow to get a safe, fast and precise dosing.

The necessity of uniformity on the finished products is essential for all kind of industries and weighing raw materials may be an error-prone operation. This is where Color Service steps in with its fully automated dosing system.

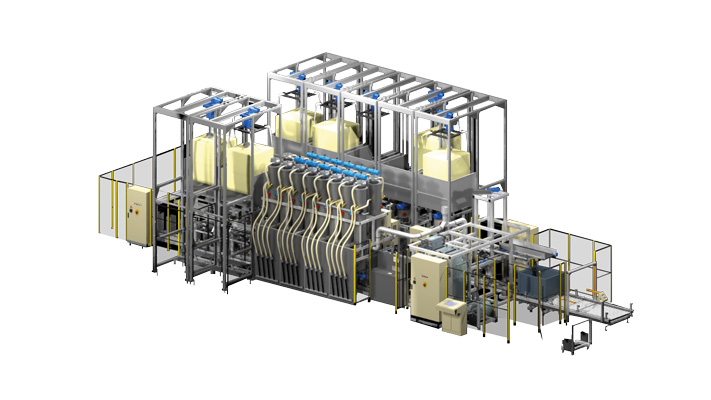

The equipment sits in the middle of the production line and automates the entire dosing process, with loading of raw materials being the only manual task. It can manage the raw materials at 360° C, to effectively reduce the overall production process time, lower the number of workers required, and eliminate the safety risk of operators working in terms of human expositions to dangerous raw materials. In fact, from an ecological point of view, Color Service has designed an innovative Anti-Dust Kit installed on each dosing head, a completely closed and aspirated system able to guarantee zero emissions in the work environment, aspirating the released dust during the dosing phase. Furthermore, the aspirated product is recovered and reintroduced into the production cycle with obvious ecological and economic benefits. The company’s highest priority is to substantially minimize environmental and ecological hazards reducing pollution and material waste to create a sustainable finished product for the customer.

A certified weighing system ensures the most accurate calculations while dosing chemicals, and a modular design allows for future modifications. It tracks the status of each recipe while it is being prepared, and every bag is labelled with a thermal transfer printed label that provides traceability to the whole cycle and process. To ensure there are no mechanical flaws or malfunctions, strict quality assurance is maintained during the system’s manufacturing. All components are run through electrical and PLC tests to check for proper functioning before they are dispatched to the client. System accuracy is verified at their facility by testing cycle time and Cpks using their products to ensure proper implementation. Customized software programs are developed internally at Color Service to supplement their products and integrate with a client’s existing systems.

Color Service further assists clients with 24/7 customer support. Operating from technological centers in America, Europe, and Asia, it offers remote help desk assistance by directly interfacing with the system to fix any issue at their factory. If remote assistance is not getting the job done, it guarantees a service executive will be present at the site within 24 hours to directly handle the issue.

Due to its decades-long experience, Color Service has mastered the art of staying ahead of the curve with innovation at its heart. Its ideology is to improve production efficiency through innovation, and the driving force for its R&D division is derived from the ideas, wants, and needs of its customers.

Color Service’s methodology of keeping customers in mind when crafting highly efficient and innovative solutions gives it an exceptional edge in the market and enables it to be a world leader in the production of automatic dosing systems.