Binova offers its customers something unique, with reduced material handling within the production plant, and proven reduced energy consumption compared to plants on the market today

Binova offers its customers something unique, with reduced material handling within the production plant, and proven reduced energy consumption compared to plants on the market today

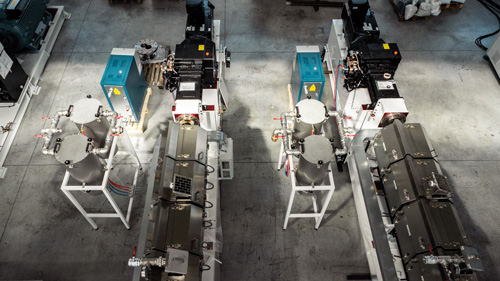

The technology of Binova’s plants, whose protagonist is the co-rotating twin-screw extruder, is capable of processing post-consumer polyolefin material in the form of ground sheet from a washing plant without the use of a cutter compactor.

The material is heated and melted totally under vacuum; thanks to this process, the creation of “frost” is inhibited, guaranteeing a high-quality end product. The plant is capable of compounding film production waste with high residual moisture, together with special granule blends. The presence of a high vacuum degassing system distributed over almost the entire length of the extruder cylinder also allows the granulation of highly printed films.

Mixing of raw materials takes place directly in the machine; from this process a perfectly homogeneous material is obtained, and consequently the quality of the final product increases.

The plant will be supplied complete with an intermediate material transport and storage station.

The production of this technology is totally made in Italy, with special attention paid to the quality of all components.

The production of this technology is totally made in Italy, with special attention paid to the quality of all components.

The competitiveness of a single step

Being able to do this type of processing in a single pass makes the line very competitive; Binova offers its customers something unique, with reduced material handling within the production plant, and proven reduced energy consumption compared to plants on the market today: for LDPE-based polyolefin materials, consumption will be no more than 0.26/0.27 kW/kg while for polypropylene or polystyrene-based materials, such as PP, PS or HIPS, consumption is guaranteed to be around 0.22/0.23 kW/kg (excluding process water cooling).

In a nutshell, Binova manages to achieve 30 percent energy savings with its co-rotating twin-screw (which has a higher degree of optimization than a traditional single-screw line),

Software and remote control

The line is equipped with software that controls all production, even at high work rates. The system has an automatic OP control panel with Internet connection, which can also be managed remotely. In this way, the technician or production manager can check the status of the line process data, even remotely. Remote control can also be used to perform troubleshooting or fine-tuning in real time.

New trade shows

This year, Binova will be exhibiting at the NPE show in Orlando, USA, May 6-10, 2024 and looks forward to seeing you at its booth.