▪ Manufacturing process: Monitoring and digitalisation

▪ Manufacturing process: Monitoring and digitalisation

▪ Additive manufacturing: La Premiere for the new 3D Print Innovatiq TiQ5 Pro

▪ ARBURG at Mecspe Lab – Innovation Space

ARBURG will be exhibiting at Mecspe in Bologna from 6th to 8th March 2024. ARBURG will be presenting itself as a technology and complete system partner for the efficient production of plastic parts. At stand C36 in hall 36, the focus will be on an application for the medical industry.

The medical sector requires very high quality and security standards, which need special attention along the entire production and material supply chain. Monitoring and digitalisation continue to be two indispensable prerequisites for the production of safe and high-quality articles. ARBURG has a great deal of experience in the development of technologies for the medical technology sector, and this is demonstrated by the full-electric ALLROUNDER 520 A 1500 400 machine, which is perfect for use in clean rooms and meets the most stringent requirements of ISO Class 7, ensuring the production of parts with high precision.

The electric machine on exhibition in the ‘Ultimate’ power version is designed for fast and complex processes. A 4-cavity mould from KEBO AG is used to produce a 9-sec syringe body in polypropylene ‘BormedTMRF825MO’ of Borealis. The particularly innovative material is able to achieve rapid crystallisation, resulting in a fast cycle time, high transparency, high gloss and a good stiffness-impact balance. The highlight of the machine are the precise servo motors of sister company AMKmotion GmbH + Co KG driven by threaded planetary roller actuators that guarantee precise and reproducible mould positioning. The toggle-type clamping unit, high-performance servo-electric drives and energy recovery during braking form the basis for the high energy efficiency of all ALLROUNDER electric machines. Enclosed, liquid-cooled drives and spindle systems operate at low noise levels, avoid dust pollution and air turbulence.

Controlled production process

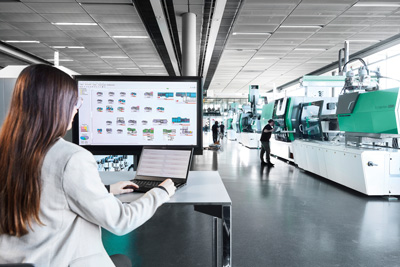

In intensive moulding processes, there are many variables to manage, and even a small deviation from set values can lead to non-conformity. For this medical technology application, the machine, equipped with the GESTICA control unit, is fitted with practical apps and digital functions to meet traceability and part quality requirements while maintaining high productivity. Practice-based operator help packages and other customised Industry 4.0 components actively support this. GESTICA control unit is user-friendly and allows direct integration of robot systems and peripheral units, ensuring fast and reliable processes. Software and machine technology interact perfectly by monitoring and adjusting the production process, maintaining stable processes resulting in zero-defect quality production.

Real-time monitoring

Knowing the process conditions in real time means efficient production or, in case of problems, immediately recognizing the anomaly and responding in time to avoid producing waste or, worse, damaging plant and equipment.

This is a digital approach where connectivity and data drive processes in order to achieve the best possible result. The application on exhibition will be connected to Arburg’s MES, the ALS computer system with which production data can be collected and analysed in real time, significantly increasing production efficiency and transparency. The system documents all relevant information in a permanent and traceable form with reference values and statistics in an up-to-date way. It actively informs you and keeps you up-to-date even on the road, with reports and reference values concerning the machines, as well as information on orders, shifts and quality.

Premiere for the new 3D Print Innovatiq TiQ5 Pro – the best in additive manufacturing versatility

Premiere for the new 3D Print Innovatiq TiQ5 Pro – the best in additive manufacturing versatility

The TiQ 5 Pro is a machine for 3D production of XL components. It is versatile thanks to its open material platform. It is a complete system with vacuum pressure bed and active heating chamber, which guarantees reliability even with long print jobs, with hard or soft materials and with fibre-reinforced or high-temperature plastics. Equipped with the GestiQ-Pro CNC system, it offers an intuitive user interface and advanced features that simplify the process. The CoreLine printhead improves accuracy and reduces collision risks. The dual extruder, capable of up to 400 °C, expands the range of materials that can be processed, offering greater flexibility. The vacuum printing table, on the other hand, ensures superior stability and adhesion, improving the quality of the finished product. The machine is equipped with a 500x400x450 mm build chamber. The SmartStart function, with its automatic levelling and nozzle calibration system, finally optimises the start of each print job, making the TiQ5 Pro ideal for a variety of industrial applications, from rapid prototyping to the production of complex components.

ARBURG is present at MECSPE LAB – Innovation Space

Wherever there is innovation and new challenges, ARBURG is always present. This year, Arburg has accepted the challenge and enthusiastically joined the demonstration initiative MECSPE LAB – Innovation Space where, together with other partners involved in the project, it works with a look to the future and sustainability.

In the MECSPE LAB exhibition area – Innovation Space at the Service Centre – the new machine of the hybrid series, launched last year in the centenary year of the founding of the Hehl family company, the ALLROUNDER 470H 1000 290 Comfort will be equipped with a mould produced using the metal additive manufacturing process. The moulded product will be a polymeric GPS component to save lives in the event of avalanches.

The new, sophisticated hybrid machine technology impresses in terms of energy savings, resource savings, production efficiency, user-friendliness and reliability. Depending on the application, with the ‘Comfort’, ‘Premium’ and ‘Ultimate’ performance variants, purchase and operating costs are reduced by up to 50 per cent and CO2 emissions are up to 12,000 kg lower. The Arburg servo-hydraulic system (ASH), already proven in the hydraulic and electric Allrounders, has also been integrated into the Allrounder 470 H Comfort and Premium models.

Thanks to the ASH, the speed-controlled, water-cooled servomotor continuously adapts the drive system to the actual power requirement. This saves up to 50% energy, especially in processes with long cooling times. In addition, the noise level of the machine is also significantly reduced.

Other factors contributing to optimised energy consumption and shorter cycle times include the new oil management concept, which requires around 35% less oil. With different injection units and numerous options, the new Hidrive series can be adapted exactly to the customer’s needs, and the combination of the electric clamping unit with a hydraulic injection unit makes it particularly interesting for those moulders who are looking for a less energy-consuming alternative to hydraulic machines, but still want to benefit from their proven advantages.