New exploration in one-step moulding of polyurethane and plastic

New exploration in one-step moulding of polyurethane and plastic

In recent years, there has been an upsurge of lightweight by replacing metal parts with plastic. Automobile manufacturers attempt to find new processes and technologies to improve the appearance of automotive trims. Simple moulding process used in the past can no longer meet the new requirements in colour, tactility, intelligentization and other aspects.

As a new type of ‘intelligent’ material, Polyurethane (PUR) has some better properties, such as good flexibility, high wear-resistance and well self-repairing performance. Furthermore, it is superior in free colour matching, bright colours, and friendly to ‘smart inserts’. Therefore, it has been widely used to the injection moulding products with decorative skins, high-quality paint or functional coatings.

To quickly react to new market trend and better satisfy customer demand, YIZUMI and Chengdu Dongri Machine Company jointly research and develop the integrated ReactPro Solution to achieve one-step injection moulding of the polyurethane and plastic. That is to produce high quality thermoplastic parts and polyurethane surface on the same machine, showing better appearance, comfortable tactility, and superior functionality.

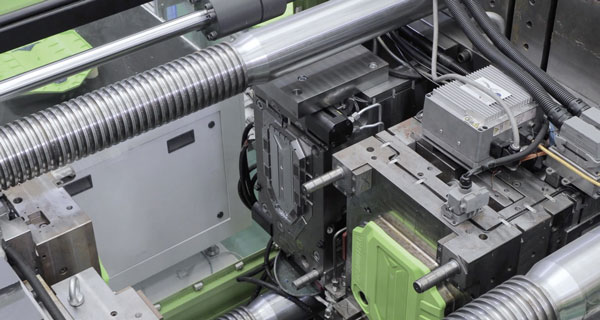

The YIZUMI UN260C-BTP ReactPro Multi-component injection moulding machines integrate the PUR reaction injection moulding equipment with vertical rotary table mould technology, which can offer rapid and precise moulding, and efficiently produce different kinds of decorative products with 3D depth of field effects or different patterns.

The machine can not only save material cost and ensure product performance but also allow PUR covering on the surface of irregular-shaped plastic parts, therefore leading to more sophisticated visual and tactility. Through the PUR filling moulding process, this machine can achieve PUR moulding thickness of 0.1- 50mm, with wider application. PUR thin-layer parts are mostly used for decorative parts such as centre consoles and operator panels, which can achieve different visual effects, including gloss, matt or 3D depth of field. Moreover, they have the characteristics of scratch resistance, aging resistance, fingerprint resistance, and self-repairing. While PUR thick-layer parts can be used for car armrests and other trims, featuring strong aging resistance and weather resistance, and as well as rich visual effects.

The machine can not only save material cost and ensure product performance but also allow PUR covering on the surface of irregular-shaped plastic parts, therefore leading to more sophisticated visual and tactility. Through the PUR filling moulding process, this machine can achieve PUR moulding thickness of 0.1- 50mm, with wider application. PUR thin-layer parts are mostly used for decorative parts such as centre consoles and operator panels, which can achieve different visual effects, including gloss, matt or 3D depth of field. Moreover, they have the characteristics of scratch resistance, aging resistance, fingerprint resistance, and self-repairing. While PUR thick-layer parts can be used for car armrests and other trims, featuring strong aging resistance and weather resistance, and as well as rich visual effects.

Compared with the traditional process, this solution integrates the injection moulding machine and the polyurethane reaction moulding equipment to achieve a one-step moulding, which greatly improves the production efficiency, reduces the cycle time and the production cost, also avoids pollution, making it more energy-saving and environmentally friendly. From the customers’ perspective, UN260C-BTP ReactPro is a cost-effective and valuable solution, which will be used in a wide field of applications, e.g. automobile, 3C products (Communication, Computer and Consumer products) and household appliances etc.

Value advantage

• The integration of injection moulding machine and polyurethane reaction moulding equipment can achieve one-step moulding of two materials (plastic + PUR) with short cycle time, high efficiency and low cost.

• Applied with rotary table mould technology to achieve fast and accurate moulding is a new exploration of ReactPro one-step moulding mould.

• This machine can achieve PUR moulding thickness of 0.1- 50mm, with wider application.

• It allows multiple product effects, such as 3D depth, different patterns, scratch resistance, and self-repairing, agile, intelligent and efficient.

• It can allow IML/IMD/IME/INS processing with the support of automatic system, to conduct film mounting under the PUR thin-layer, ensuring that products not only have beautiful appearance but also more functions.

• The injection moulding machine control system can not only offer editing functions to meet special mould and process requirements, but also provide various integrated solutions of special process control software.

• PUR reaction molding system

a. Support zero-downtime operation to maintain the stable system

b. Flow Range≥3g/s

c. Machine Capability Evaluation Index CMK>2.3

d. No bubbles on the product surface to achieve Class A surfaces

• The communication control system of integrated PUR reaction moulding equipment can achieve unified adjustment of process parameter, with well-designed and user-friendly control panel.