Modular and easy to use, this range of equipment can be applied on all extrusion lines, blow moulding machines and injection presses to dose gravimetrically, mix up to a maximum of 6 components. It ensures a very high level of precision.

Modular and easy to use, this range of equipment can be applied on all extrusion lines, blow moulding machines and injection presses to dose gravimetrically, mix up to a maximum of 6 components. It ensures a very high level of precision.

Founded in 1975, Engin Plast has a long experience in the business of dosing units, supervision systems, recovery and conveying of plastic and non-plastic materials. Its mission has always been focused on creating innovative and customized solutions, capable of guaranteeing a tangible and lasting benefit. Machines and systems are all designed and manufactured at its factory in the province of Ferrara in order to provide its customers with high quality and reliable products over time. The range of equipment offered by Engin Plast is intended for all application in the plastics market such as extrusion, blow moulding, injection, in-line and off-line recovery scraps.

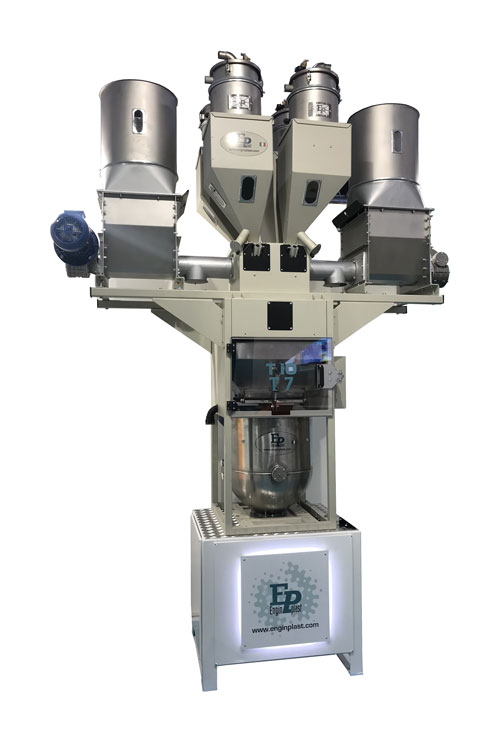

TRIO GRAVIMETRIC DOSING SYSTEM

Gravimetric systems are equipment for dosing plastic materials by electronic balance applied to the dosing units. The configuration of these systems can be different depending on the application and on the type of raw material to be dosing. The TRIO range is mainly based on the weight sum technology (batch), i.e. all the materials are weighed in a single scale sequentially and cover the entire range of applications required by the market starting from small-sized models (min. capacity 20 kg/h) up to reaching capacities of 2000 kg/h. Gravimetric dosing systems applied to the extruder feed allow to obtain advantages in terms of precision and repeatability of performance over time, furthermore they allow to reduce to a minimum the typical tuning operations of volumetric systems.

TRIO range can be applied on all extrusion lines, blow moulding machines, injection presses to gravimetrically dose and mix up to a maximum of 6 components (polymers in granules, masterbatch, regrind material). The gravimetric system can be installed directly above the process machine in place of the feeding hopper, or it can be positioned on the ground to feed one or more lines. In recent years Engin Plast has worked on various fronts, specializing in processing of difficult materials such as powders and/or regrind materials; the modularity and ease of use of the machine as well as management and supervision with software allow full integration with the customer’s plants and systems already in use. The control of the dosing units is implemented with the use of a touch screen panel, with an intuitive operator interface created by a synoptic software. All process parameters can be collected and analysed both locally and remotely. Engin Plast has recently developed a gravimetric batch dosing system suitable for feeding extrusion lines capable of treating 100% of regrind material. The TRIO T7 and T10 models are the evolution of this need, capable of dosing very light regrind materials 0.2 kg/l bulk density, reaching significant flow rates of up to 2000 kg/h, particular attention has been paid to the mechanical parts to be able to overcome the critical points (mixing of the various components, conveying, storage, etc.) that these type materials can create.

DOSING, CONVEYING AND GRINDING SYSTEMS

Today Engin Plast is able to provide at its customers integrated system solutions and the logic of which is that create an automating interaction of the various systems such as storage, conveying and dosing systems for raw materials on an extrusion line, also providing, when required, an in-line grinding/waste recovery system, in addition to all this is the provision of an advanced control system for the management and supervision of the plant.

The Engin Plast proposal is completed with the range of TRIX granulators, which offers integrated solutions between the recovery, management of production waste and their reuse in mixtures created by TRIO dosing systems in eco-sustainable transformation processes.