High-performance compounds, broad product portfolio, internationalization and sustainability are the four key concepts that explain Sirmax Group’s growth and success

High-performance compounds, broad product portfolio, internationalization and sustainability are the four key concepts that explain Sirmax Group’s growth and success

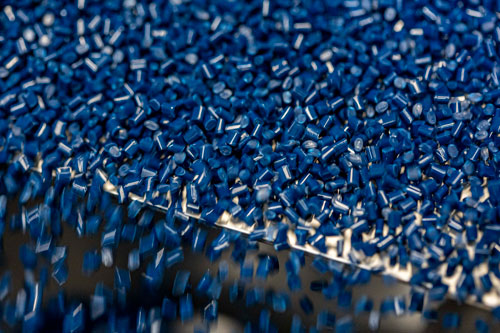

High-performance compounds, a broad product portfolio, internationalization and sustainability. These are the four key concepts that explain the growth trajectory and success of the Sirmax Group. The Group’s successes are marked by an important milestone this year: The company’s 60th anniversary. Founded in Isola Vicentina in 1964 under the name Sirte (Società Italiana Resine Termoplastiche, Italian Thermoplastic Resins Company), the company – headquartered in Cittadella (Padua) and specialized in the production of thermoplastic granules for various application sectors – has always based its growth on the ability to have an ambitious and far-sighted vision, while adapting to the changes and needs of the market, and always remaining close to its customers.

The production of high-performance compounds and the vast number of materials handled – the first key concepts – have always been fundamental, and three milestones in Sirmax’s history are proof of this. The first one was reached in 2016, when the acquisition of a local company allowed Sirmax not only to grow by external lines, but also to expand its product portfolio by incorporating and developing even more technically high-performance engineering polymer and styrene resin families. The second was reached 2019, when a brand-new plant in Poland was entirely dedicated to the production of thermoplastic elastomers. A third milestone was the acquisition in 2020 of a 50% stake in a university spin-off, Smart Mold, which specializes in injection molding engineering and the design of products with innovative simulation systems.

Internationalization is the second key concept for understanding Sirmax. The presence of foreign markets has always been seen as a way to be close to Sirmax’s plastic buyers. For this reason, plants were opened first in Poland in the early 2000s, then in Brazil, India, and the USA, bringing the same expertise and technology as the parent company to each production site. Sirmax has internationalized by shortening its customers’ supply chain and creating its own local, loyal, and flexible supply chain downstream. It is precisely thanks to this ‘short’ supply chain, which is well-organized and can be adapted quickly to market demands, that it has been possible for the Veneto-based company to face difficult times, such as the Covid crisis.

Sustainability, the third key concept, is the Sirmax Group’s present and future. Since 2019, which is when the group began to invest heavily and consciously in the circular economy, Sirmax has been processing plastic from urban waste collection through integrated plants and its own technologies, creating formulations based on precise customer requirements with the same approach and expertise with which virgin raw materials – the company’s core business – are processed. The company therefore produces compounds ready for use in applications in the household appliance, automotive, electrical, furniture, and accessories sectors. Thanks to the integrated recycling and compounding process that takes place within its plants, Sirmax is able to process post-consumer plastic waste (selection, washing, shredding), and to ennoble it with the addition of mineral fillers or reinforcing fibers until it becomes a material suitable for the production of durable goods. These goods are stronger, higher-performance structural components with a lower carbon footprint. This process has made it possible to create innovative product families that can replace the use of virgin materials but with a lower carbon footprint due to the recycled raw material content.

Today, Sirmax is entering a new chapter. The company is celebrating its 60th anniversary by looking to the future, which is made up of a more structured approached to management, greater openness to the market, and greater internationalization, while maintaining the proximity to customers that has distinguished it to date. Globally, many regions are growing, and many challenges must still be faced. For example, the current “Making in India” policy helps grow domestic manufacturing and reduce Indian industrial dependence on other countries, primarily China. It is no coincidence that Sirmax has decided to focus even more on India: After establishing two factories, active since 2017, a third is about to be built. This new facility, which will become operational in 2026, will be the Group’s 14th.

Sirmax will be present at Fakuma fair 2024, hall B2 – booth 2209.