Thanks to investments in advanced digital solutions such as artificial intelligence and the Internet of Things (IoT), Binova is ready to revolutionize how it produces, manages data, and interacts with customers

Thanks to investments in advanced digital solutions such as artificial intelligence and the Internet of Things (IoT), Binova is ready to revolutionize how it produces, manages data, and interacts with customers

Binova’s technology, which centers around the co-rotating twin-screw extruder, is capable of processing post-consumer polyolefin material in the form of ground film, coming from a washing plant, without the use of a cutter compactor.

Company news: Innovation and growth with the new website, plant, hires, and technologies

The company is undergoing a period of significant transformation, marked by important innovations that strengthen its position in the market and prepare it for future challenges. These changes span various areas, from the move to a new plant, the launch of a revamped website, to new hires and the adoption of cutting-edge technologies for managing the production process.

New website: Greater accessibility and usability

New website: Greater accessibility and usability

In an era where online presence is crucial, Binova has decided to completely overhaul its website. The new platform has been designed with a modern, intuitive, and responsive layout aimed at improving user experience on both desktop and mobile devices. Among the key updates are simplified navigation, a section dedicated to company news, and a reserved area for stakeholders to access detailed information on products and services.

The website also serves as a true communication hub, offering real-time updates on the company’s progress and initiatives.

New plant: More space for innovation and production

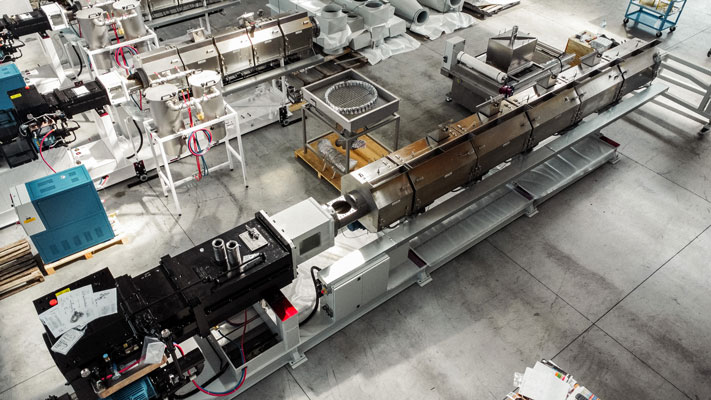

In the past year, the opening of a new production facility, designed to meet the growing demand for the company’s products, has marked a major milestone. Located in a strategic area, just 20 minutes from Milan Malpensa Airport, the new plant boasts advanced production technologies, larger spaces, and improved logistics. The aim is to increase production capacity, reduce lead times, and improve product quality.

New hires: Team growth and innovation

With the expansion of business activities and the acquisition of new projects, it was inevitable that Binova would need new talent. For this reason, recruitment has been initiated to strengthen the team in various areas, from engineering and research & development to marketing and purchasing. The goal is to attract qualified and motivated professionals who can tackle the challenges of a constantly evolving market.

New technologies: Innovation at the core

Finally, the adoption of new technologies represents one of the pillars on which Binova is building its future. Thanks to investments in advanced digital solutions such as artificial intelligence and the Internet of Things (IoT), the company is ready to revolutionize how it produces, manages data, and interacts with customers.

Among the implemented technologies, real-time production monitoring systems stand out, allowing the company to analyze and optimize every stage of the process. The adoption of cloud technologies and advanced software solutions enables the optimization of workflows, improves business efficiency, and accelerates innovation. With these new technologies, the company is positioning itself at the forefront of its sector, ready to meet increasingly demanding market needs and to compete successfully in global markets.

Conclusions: A promising future

With the launch of the new website, the opening of the new plant, the hiring of qualified talent, and the adoption of advanced technologies, Binova is demonstrating its readiness to seize future opportunities. Each innovation represents an important step toward modernization and growth, with a focus on continuous improvement and innovation.