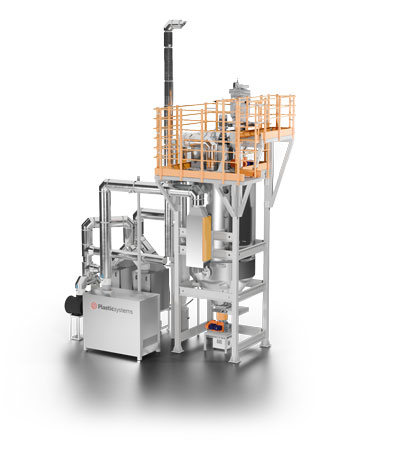

Plastic Systems presents the CRN crystallizer, designed to enhance the crystal lization process and optimize the drying phase of plastic materials

lization process and optimize the drying phase of plastic materials

The CRN is a crystallizer designed to enhance the crystallization process and optimize the drying phase of plastic materials. This machine, primarily used for processing materials in the form of flakes or granules, is the result of an innovative design aimed at ensuring high efficiency and consistent quality in polymer processing.

Operation and features of the CRN

At the core of the CRN crystallizer is its low-speed agitation system with a vertical shaft, minimizing dust generation during the process. The design of the CRN has been specifically conceived to surpass the glass transition temperature of plastic materials, a critical point for crystallization. This ensures homogeneous crystallization and optimal material flow without compromising the final product’s quality. The heating process and temperature control are managed by a PLC, which regulates the process temperature and allows for continuous monitoring of operating parameters through temperature and level sensors. Another crucial feature is the insulation, which reduces heat loss and improves overall energy efficiency, maintaining a constant temperature in the material during treatment. Additionally, the hopper is designed to handle poorly flowing materials, such as regrind or flakes, ensuring a continuous flow without blockages.

The ventilation system of the CRN is another strong point. With a high-flow ventilation unit, the machine ensures proper heating and air distribution through the material, contributing to increased crystallization and dehumidification kinetics. This helps reduce the moisture content of the material to below 800 ppm, a significant improvement that enhances the quality of the final product.

Solutions for easy maintenance

Access to the interior of the crystallizer is facilitated by a large hinged and insulated door, allowing for quick and safe inspection of internal components. These technical details contribute to making the CRN a machine that is easy to manage and maintain.

Applications and capacity

The CRN is available in various versions, with models ranging from 50 liters to over 7000 liters in capacity. This wide range of sizes enables the crystallizer to handle even the highest hourly throughputs, making it adaptable to different production needs. Due to its versatility, it is particularly suited for processing plastic materials in various sectors, from recycled plastic producers to more complex industrial applications.

The rotary valve feeding system ensures a constant supply of material, while the cyclonic depowdering and condensation system ensures effective removal of contaminants, maintaining the purity of the processed material. This system is particularly important for maintaining high quality standards, preventing dust or other impurities from compromising the final result.

Conclusions

In summary, the CRN crystallizer for plastic materials represents an advanced and highly efficient solution for processing flakes and granules. With its functional design, high-flow condensation, and ventilation systems, the CRN ensures excellent performance, optimizing crystallization and improving the overall efficiency of the production process. With models capable of handling both small and large throughputs, the CRN proves to be an indispensable ally for companies working in the plastic processing industry.