After celebrating sixty years in business and successfully concluding 2024, Sirmax Group is looking ahead to the challenges of 2025 with confidence

After celebrating sixty years in business and successfully concluding 2024, Sirmax Group is looking ahead to the challenges of 2025 with confidence

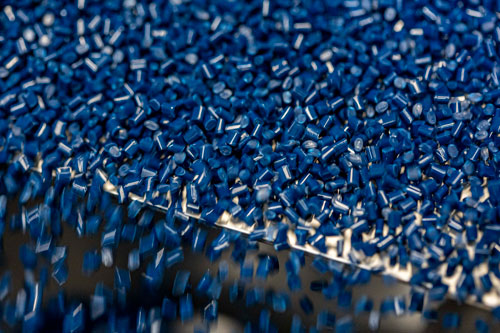

After celebrating sixty years in business and successfully concluding 2024, Sirmax Group, headquartered in Cittadella (Pauda) and specializing in the production of thermoplastic compounds for various application sectors – including automotive, household appliances, furniture, electrical, construction – is looking ahead to the challenges of 2025 with confidence.

The new year started in the best possible way, marked by the achievement of the Great Place to Work® certification for all Italian plants (Cittadella-Padova, Tombolo-Padova, San Vito al Tagliamento-Pordenone, Pianiga-Venezia, Salsomaggiore Terme-Parma, Isola Vicentina-Vicenza). This recognition, which builds on the 2023 certification, reaffirms the company’s commitment to fostering a stimulating environment and a positive culture focused on well-being and continuous improvement for all employees.

Sirmax will maintain its presence at the industry’s leading trade fairs, from Italy (Mecspe and GreenPlast) to the United States (Plastics Recycling Conference, EAV SHOW, and TPO), from France (Nemmo) to Germany (VDI, K, and EUBC), as well as at Electro-Plast in Belgium. Notably, the company will participate in the fourth edition of Plástico Brasil – International Plastic and Rubber Exhibition, one of Latin America’s most significant trade fairs for the plastics and rubber industry, taking place from March 24 to 28, 2025. Brazil, where Sirmax operates a production plant in Jundiaí (São Paulo), remains an increasingly strategic market as the company continues to expand and gain market share. With the Latin American market experiencing steady growth, Sirmax is ready to seize new opportunities, focusing primarily on the automotive sector while also monitoring developments in other industries.

Sirmax will maintain its presence at the industry’s leading trade fairs, from Italy (Mecspe and GreenPlast) to the United States (Plastics Recycling Conference, EAV SHOW, and TPO), from France (Nemmo) to Germany (VDI, K, and EUBC), as well as at Electro-Plast in Belgium. Notably, the company will participate in the fourth edition of Plástico Brasil – International Plastic and Rubber Exhibition, one of Latin America’s most significant trade fairs for the plastics and rubber industry, taking place from March 24 to 28, 2025. Brazil, where Sirmax operates a production plant in Jundiaí (São Paulo), remains an increasingly strategic market as the company continues to expand and gain market share. With the Latin American market experiencing steady growth, Sirmax is ready to seize new opportunities, focusing primarily on the automotive sector while also monitoring developments in other industries.

With a strong emphasis on sustainability, the company’s key research and development investments are increasingly directed toward producing high-quality polypropylene compounds with post-consumer recycled content, offering mechanical properties comparable to those of virgin compounds. Sirmax is also advancing projects in the automotive sector that enhance structural and aesthetic solutions, improving mechanical performance, temperature resistance, and UV protection for vehicle interiors. Encouraged by positive trends in recent years, the company is considering further investments in this area.

On a global scale, Sirmax will continue to strengthen its presence in the electrical and electronics sector in 2025. This sector, which saw significant growth for the company in the first half of 2024, requires high-performance compounds that meet stringent international standards. To address this demand, Sirmax is increasing production of flame-retardant compounds – materials designed to suppress, reduce, and delay the spread of flames – and has expanded its facilities in the United States and Poland. This aligns with the market’s increasing focus on fire safety and the growing adoption of electric batteries, which is driving manufacturers to prioritize safer materials. Sirmax’s self-extinguishing compounds are formulated not only for automotive components but also for a range of applications, including plinths, hobs, and power tool parts such as electric welders. Additionally, halogen-free formulations are available. To meet the growing demand for sustainable materials, the company also offers a broad portfolio of products with a lower carbon footprint (compared to prime virgin), formulated with pre- and post-consumer raw materials, suitable for both civil and industrial applications.

“Today’s market presents significant challenges and is becoming increasingly demanding,” says Massimo Pavin, President and CEO of Sirmax Group. “Thanks to product diversification, organizational renewal, and the speed that has always set us apart, we are ready to meet our customers’ needs and are working to raise the bar even higher. We look forward to 2025 with confidence.”